Whether your business or organization uses traditional or digital marketing channels, there’s always a need for printed marketing collateral such as brochures, business cards, posters, and the like. When you’re in charge of ordering printed materials, do you know the common concepts and terms used in the print industry? It helps to understand them so you’ll know exactly what you’re getting.

Here are some of the commonly used printing concepts and terms to get you started:

Printing Processes:

Offset Printing (Offset Lithography)

Offset printing presses apply layers of ink one color at a time. It’s often used for higher quantities.

Digital Printing

Digital printing machines apply all colors in one pass. It’s often used for lower quantities.

Color Abbreviations:

When you ask for print quotes, you’ll notice that printing vendors/brokers use abbreviations for the number of colors applied to paper. Here are the most common options:

- 4/0 = four colors on one side, none on the other (offset or digital).

- 4/1 = four colors on one side, one color on the other (offset). In digital printing, if one side is in full color, then the other side is too, even if you choose to use one color only.

- 4/4 = four colors on both sides (offset or digital).

- 1/0 = one color on one side, none on the other. Can be black only (offset or digital) or onePantone (PMS) color in offset printing.

- 1/1 = one color on each side. Can be black only (offset or digital) or one Pantone color in offset printing.

Coatings:

We use coatings to protect printed pieces from scratching and smearing. In addition, coatings can also create a variety of visual effects. Here are the most commonly used coatings:

Aqueous Coating

Applied on offset or digital printed pieces, aqueous coating is water-based, clear, and quick-drying. Available in a gloss or matte finish, it helps seal the ink and keep pieces from yellowing. Due to its water content, it’s also more environmentally friendly than other coatings.

If you need people to write on your printed collateral, then use pen/pencil receptive AQ coatings.

UV Coating

UV coating, which combines polymer resin with ultraviolet light, protects pieces more than aqueous or varnish coatings. Applied to offset or digital pieces, there’s much more variety in UV coatings including gloss, matte, satin, and other special finishes.

Applying spot UV means that you can specify exactly where you want a UV treatment in your artwork such as a logo or image. The downside to UV when applied over entire sheets is that the coating can crack when folded or scored.

Varnish Coating

Applied during the offset printing process, varnish coatings come in gloss, satin or matte and with or without a tint. You can use them to cover the entire surface or choose a spot varnish to highlight a specific area. But, keep in mind, that they offer less protection than aqueous or UV coatings and can yellow over time.

CS1 = coating applied to one side only.

CS2 = coating applied to both sides of the paper

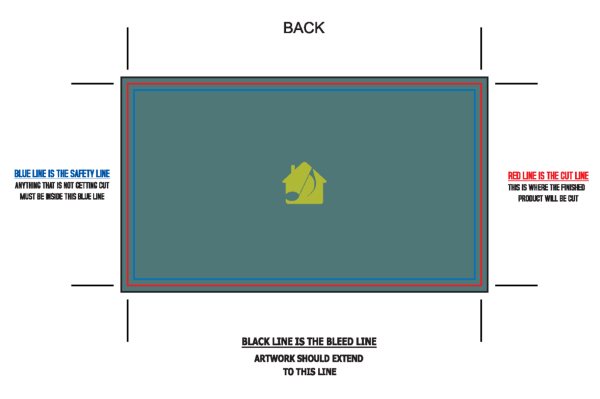

Bleed:

When you want an image extended right to the edge, you’ll need to create a bleed. This allows your artwork to fill the entire space without a border. Most professionally designed artwork today includes a bleed.

Do you see how the green background extends past the red cutline? That 1/8th inch is the bleed. Finishers trim the piece on the red line.

Check back for Part 2!