How Temperature Monitoring Helps Improve the Supply Chain for Healthcare Startups

By: Vikas Agrawal

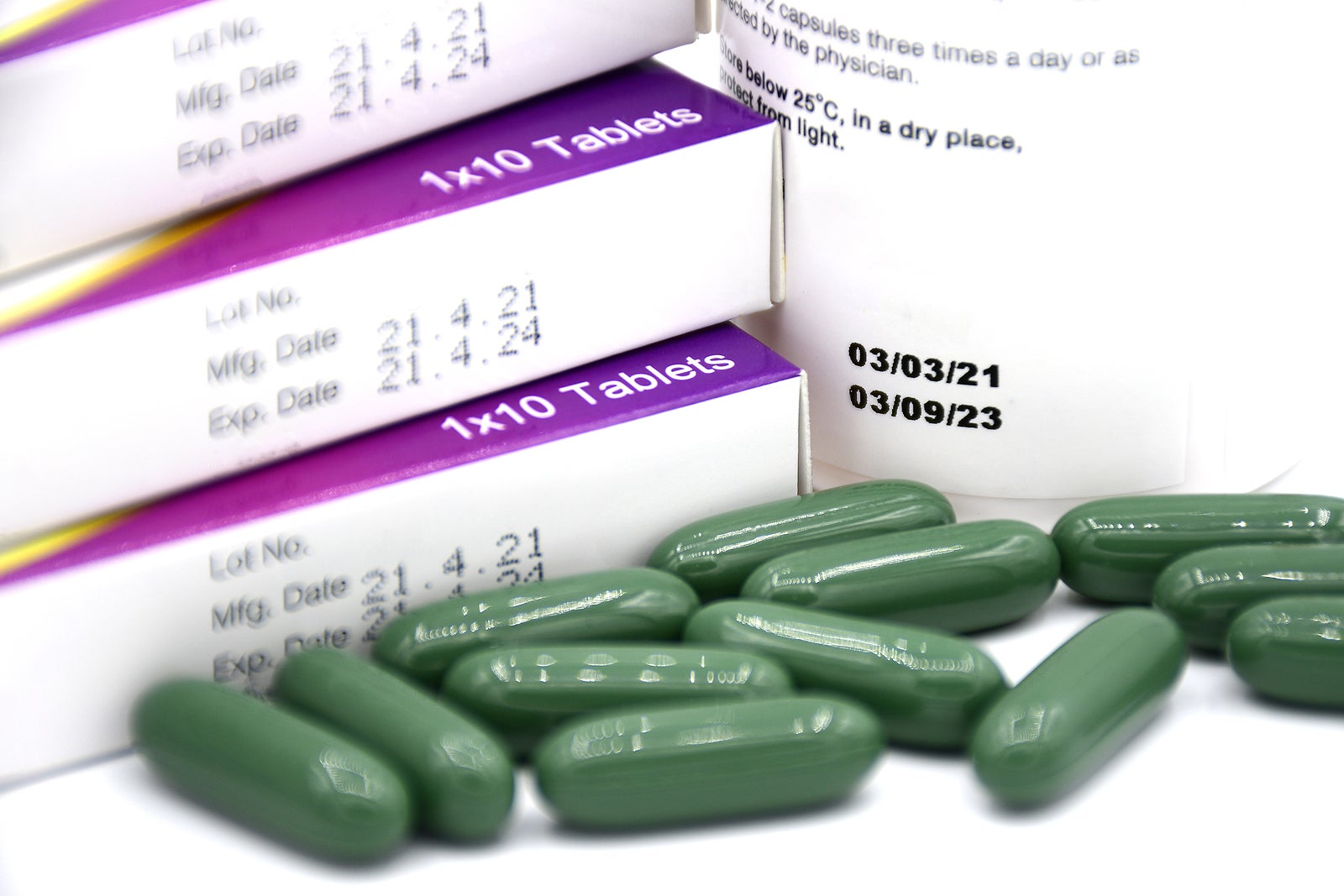

Offering an innovative product that helps people’s wellbeing is where it all starts, but supply chain quality is likewise essential to any healthcare startup’s success. Manufacturing the best supplements or gadgets won’t generate revenues unless you deliver the product to retail shelves and end consumers in optimal condition.

Today, internet of things (IoT) technology helps healthcare startups optimize their supply chain processes, from procurement to last-mile deliveries. Central to these optimization efforts are temperature monitors for logistics. On the surface, these devices appear to be nothing more than thermometers. However, the data they collect and transmit offer companies a wealth of supply chain insights.

Startups in the wellness space use these datasets and design more efficient product distribution processes. Here are some key benefits of using temperature monitors.

Reduced Waste

Waste is a major issue in supply chains worldwide. The food supply chain often receives flak for the tons of waste it generates every year. Healthcare supply chains don’t occupy the headlines as much, but waste creates problems that are just as severe. Because defective healthcare products could result in deaths and disease, regulators and businesses need to be extra vigilant about quality assurance, and as a result, there’s often the need to destroy merchandise.

On the commercial side of the equation, companies spend significant resources conducting research to develop new medicines, natural extracts and dietary supplements. Approval cycles are lengthy too. Losing products that are so costly to create to supply chain waste is frustrating, to say the least.

Products such as vaccines, drugs, and precision equipment are especially sensitive to high temperatures, which are common during shipping. Temperature monitors help supply chain stakeholders monitor conditions to ensure they don’t exceed designated temperature thresholds. Thus, a critical portion of the supply chain is automated. If a shipment approaches a threshold, alerts notify stakeholders of the situation, and they can take mitigative action.

These temperature alerts also establish a performance pattern for all vendors involved. For instance, if a logistics vendor has a lengthy history of violating temperature thresholds, they might lack the infrastructure and expertise to handle sensitive shipments.

The result is a performance map that healthcare startups use to identify the best vendors for their products. By relying on performance trends generated from temperature monitoring data, healthcare startups can deliver safe products to their consumers.

Better Shipment Routing

How hard can it be to design a shipping route? Pretty hard, as it turns out. One might think the best route is the shortest distance between two points. However, the logistics world begs to differ. Variables such as fuel consumption, government regulations, en-route infrastructure, and weather play a significant role in route design.

These variables are significant before considering others, such as geopolitical factors and risky political zones. The result is a confusing web of variables that makes route planning challenging. Throw different transportation modes into the mix, and the challenge is obvious.

Temperature alerts offer significant inputs to route planning models. Healthcare logistics partners use sophisticated software, usually AI-driven, to design optimal routes. Historic temperature notification datasets validate the route’s efficiency.

For instance, AI might design a route and check whether it is an efficient one by verifying past temperature notifications. Excessive threshold violations point to some deficiency along that route, such as poor infrastructure or vendor facilities. Thus, even if that route offers the quickest deliveries, it isn’t reliable since shipments will likely arrive in less than optimal conditions.

Maintaining this delicate balance between product condition and timely deliveries is impossible without regular temperature notification data. A healthcare startup can quickly check logistics timelines and potential routes when conducting demand planning exercises.

Thanks to the abundance of data from temperature notification systems, healthcare manufacturers receive deep insights into their logistics and supply chain.

Mitigate Risky Market Trends

Healthcare startups are all about data, and predictive analytics platforms allow business leaders to crunch vast quantities of data to create demand models, plan procurement chains, and suggest pricing strategies. These are sophisticated data processing engines, but without the input of temperature notification signals, even the best platforms will struggle to offer useful insights.

When planning demand, a company’s ability to effectively store and source material is critical. A pattern of temperature violations at a company’s on-site warehouse reveals inadequate storage facilities. This company would be better off manufacturing products in small batches, thus eliminating large-scale demand generation strategies.

In turn, this decision affects everything from marketing to sales and pricing. For instance, the company would be ill-advised to generate excess demand by offering product discounts or running sales promotions. Temperature notification data also helps healthcare startups evaluate procurement quality.

Using these datasets, they can create facility-specific KPIs such as the number of on-time deliveries, or the percentage of deliveries in optimal conditions. These metrics are essential to designing robust manufacturing and production schedules.

Small, Yet Significant

Temperature notification data is a small yet significant part of the healthcare supply chain. Startups worldwide are leveraging temperature data by using it as input for sophisticated models when evaluating process efficiency and vendor performance.

In short, temperature data might be a tiny portion of a vast field. However, it is a significant one.

2563 Views