Entrepreneurs are creative, big thinkers who look at the wider picture and long-term goals. However, when you manage a business, it’s also vital to consider details, including ways to limit risks. It may not be the sexiest topic of all, but reducing business risk is crucial if you want to maximize profits and have your operation around for many years.

In particular, be sure to keep employees and shipping contractors safe at all times and reduce liability. If your firm has to ship dangerous goods at any stage, this is one area where understanding and reducing risks is critical. Here’s what you need to know today about the logistics of moving hazardous items.

Be Clear about Classifications

You can’t handle dangerous goods appropriately if you’re not even sure what’s classified as hazardous for some reason. Many commonplace items can fall into this category that you may not realize, such as perfume, paint, batteries, and even nail polish. As such, learn exactly what’s considered dangerous.

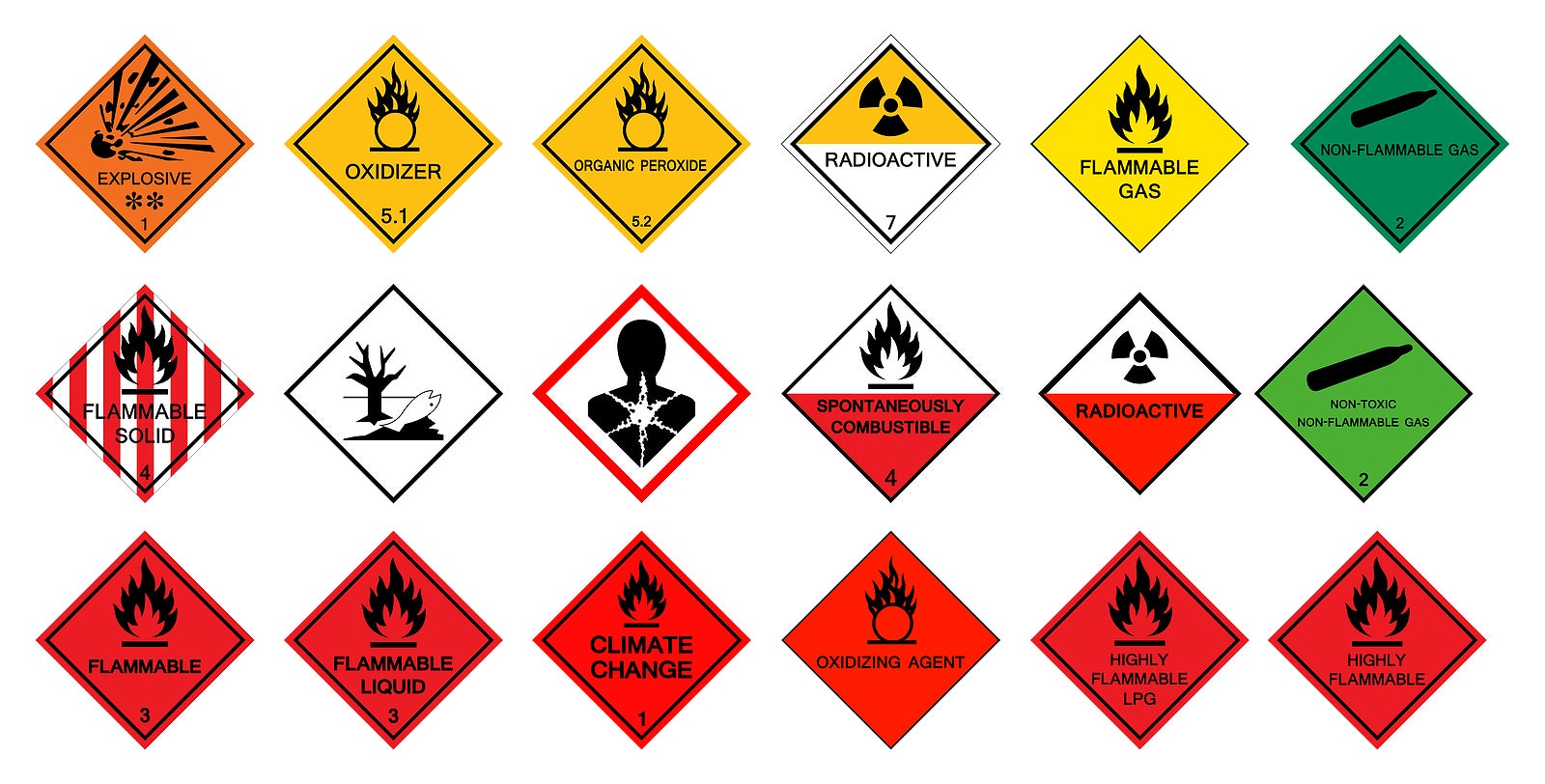

Be careful with any items that have some inherent property that could pose a risk, if not controlled effectively, to the world and environment at large and to living organisms of any type. Hazardous things can be gases, liquids, or solids. They can be hot or cold, or any temperature in between, and have a strong smell or be odorless. Plus, dangerous goods can have varying negative effects, including catastrophic ones.

When determining if something is hazardous, consider if it’s poisonous, explosive, or flammable, for starters, although it might also pose a risk for some other reason. Items fall into different dangerous categories, and each of these requires goods to be handled and transported differently to ensure safety. Each nation, and sometimes different states or territories, too, have their own rules about the classifications of materials, so always check regulations at relevant destinations.

Train Employees in Correct Procedures

If your business ships any kind of dangerous goods, train your workers on the correct procedures in handling these things and in creating appropriate paperwork for them. Anyone in your team, including in-house staff members and external contractors, should know how to stay safe and reduce risks. They need to be clear on the specific tasks they must complete on their end, including the order of such jobs.

Make everyone aware of potential consequences if they don’t follow the steps correctly. They should know how to protect themselves, their co-workers, and other people along a shipment’s route. Plus, they also need to understand the possible business impacts if they don’t take their responsibilities seriously. For instance, your firm could be fined, told to close for a period, face legal action, or have other consequences to deal with if non-compliance occurs.

Pack and Track Goods Effectively

Moving risky goods requires focusing significantly on packaging items correctly and tracking them along their journeys. To ensure dangerous things won’t harm anyone, you and your team must select the right containers to house materials. Packaging should provide plenty of cushioning, have proper closures that won’t come undone in transit, and feature absorbent materials to contain leaks.

Developing the right packaging starts early on in the process. It’s not just about how items fare while being moved, but also ensuring parcels are safe when staff members and transportation workers, customs officials, and other people handle them at other times.

When goods are en route to their final destination, you should use products to warn transporters about the contents, so they know to be careful. Utilize a quality temperature indicator on parcels so people can see if goods have become more dangerous along their journey.

Put Safety Protocols in Place

Another way to increase safety is to put detailed protocols in place for everyone in your business to follow. For example, create a checklist that everyone who has anything to do with hazardous goods can follow. Take advantage of tech software designed to track shipments, too. These tools can provide real-time information people need at every step along the way, so no one is ever in the dark.

It pays, too, to set up checks and balances to further boost safety. Make it a protocol, for instance, that at least two people read labels for risky items to ensure the correct information is listed.

You can also request that workers do separate jobs, such as one-person packaging goods, another signing off on this work, and another taking a photograph of parcels to document their condition. Protocols like these help to reduce the chance of mistakes happening.

Shipping dangerous goods takes more time, energy, and commitment than standard parcels, it’s true. However, handling these items doesn’t need to cause insurmountable problems for your business, so long as you follow the steps above.

2118 Views