No Need to Overreact About Automation Replacing Jobs

By: SmallBizClub

Experts estimate that 35% of the jobs of today will be eliminated within the next 20 years. The industrial age is coming to an end, and being replaced by the technological age. For many businesses, the shift can’t happen quickly enough. Those who have edged ahead of the competition by implementing new technologies have left others scrambling to either do the same or create even more advanced technologies themselves. Companies that do neither don’t fare very well, and often, don’t survive.

Automation and Job Elimination

The Harvard Business Review reports that the average “lifespan of a company on S&P 500 has decreased from 61 years to 18 years.”

These statistics have caused even business executives to fear that automation may be coming for their jobs next. Many non-executives have lived with that fear for quite some time.

Many are concerned that automation will one day replace human workers entirely, since robots don’t have to be paid wages. Those most concerned will find comfort in a recent article that points out that technology is creating more jobs than it’s making obsolete.

There is other evidence to suggest that growing public concern about increasing joblessness due to automation may be an overreaction to a normal period of social adaptation to new technology. In a recent interview with Business Insider, McDonald’s CEO Steve Easterbrook said that McDonald’s “won’t replace workers with machines—even if restaurant operators have to pay the $15 hourly wage that protesters are demanding.”

How Some Job Elimination Can Be a Good Thing

The potential for eliminating some of the most dangerous jobs is cause for celebration. Imagine robots, rather than humans, working in the mining industry. It’s estimated that mining accidents still claim about 12,000 lives every year. The death of thousands more are attributed to conditions associated with exposure to coal dust, such as black lung.

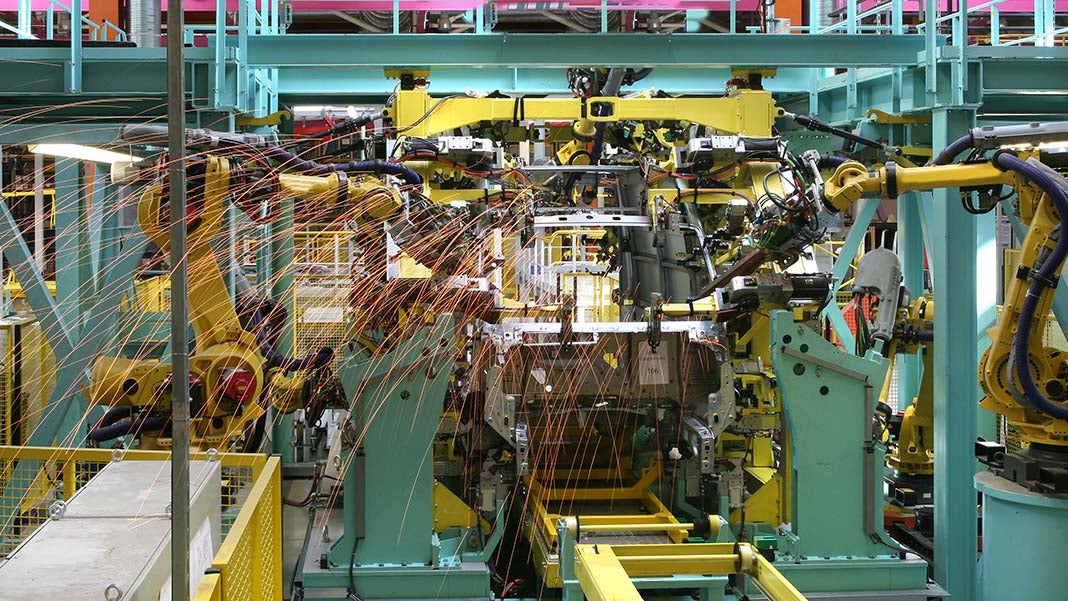

Assembly line workers often suffer life-altering injuries as the result of heavy lifting and repetitive motion. Robots can lift hundreds of pounds repetitively, leaving humans free to pursue careers in robotics. This illustrates the reality that every new technological advance creates a host of new jobs required to sustain it.

Rather than just eliminating jobs, technology is making jobs less repetitive, more interesting, and more efficient. Some technology, like professional office management software, also make jobs more, rather than less, human. For example, by automating repetitive tasks such as billing and scheduling, health care professionals are able to spend more quality time communicating with their patients.

Many businesses that utilize software specifically designed for their industries report an increase in sales, which allows them to expand and hire more people. They also report increased customer satisfaction, since unlike humans, computers never forget.

Advances in Robotics

Computers have taken over many jobs that it was once believed only humans could do. Tax preparation, x-ray analysis, and gathering evidence for legal proceedings are just a few examples. Computers can only do what humans program them to do, and the same is true of robots.

The initial cost of robots prevents many businesses from utilizing them. A complete robotic system with controllers and accessories costs between $100,000 and $150,000 and a single industrial robot costs between $50,000 and $80,000. Robots also have to be segregated from human workers to prevent the possibility of injury, since they are not self-aware.

However, those limitations are being removed as the science of robotics continues to make advances. One of the most recent advances in robotic design is Baxter. Designed by Rodney Brooks, inventor of the Roomba, Baxter is the first robot able to work alongside humans safely. Unlike other robots, Baxter can look around by shifting its “eyes” which allows it to perceive humans nearby. Baxter is also smarter than other robots.

Previous versions of industrial “workbots” required high-paid programmers to write and debug copious amounts of code to enable the robot to perform even the simplest task. Training Baxter is as easy as physically manipulating its arms to perform the motions you want repeated in the correct sequence. Finally, Baxter is priced at only $22,000.

Rather than being fearful of being replaced by robots, we should give thanks that automation may save us from serving as robots ourselves.

Author: Philip Piletic is a freelancer, writer and traveler who loves to share his experience about business, marketing and tech. Thanks to Costa Pinchuk from Praktika.

Author: Philip Piletic is a freelancer, writer and traveler who loves to share his experience about business, marketing and tech. Thanks to Costa Pinchuk from Praktika.

2920 Views