Role of Fiber Laser Cutting in Advancing Sustainable Practices for American Businesses

By: SmallBizClub

In recent years, fiber laser cutting has emerged as a groundbreaking technology that aligns with the sustainability goals of modern American businesses. This precision-based technique uses focused laser beams to cut materials with remarkable efficiency, reducing waste and energy consumption. As businesses strive to minimize their environmental footprint, fiber laser cutting offers a strategic advantage by enabling cleaner production methods without compromising output quality. Industries such as automotive, aerospace, electronics, and green construction are increasingly adopting sustainable laser cutting practices, recognizing its potential to contribute to a greener future.

What is Fiber Laser Cutting, and How Does it Work?

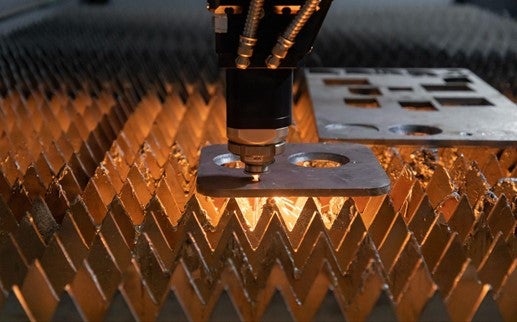

Fiber laser cutting is a technology that utilizes a high-intensity laser beam, generated through fiber optics, to cut materials accurately and quickly. This laser system operates by amplifying light within a flexible optical fiber, which is then directed to a precise point on the target material. The high-energy laser beam melts, vaporizes, or removes the material, resulting in an accurate and refined cut. Advanced machines like ACCURL fiber laser cutters provide precise, efficient cutting, accommodating a range of materials with impressive speed and accuracy. Fiber laser systems are known for their compact design, minimal energy requirements, and high adaptability to various materials.

Fiber laser cutting is a technology that utilizes a high-intensity laser beam, generated through fiber optics, to cut materials accurately and quickly. This laser system operates by amplifying light within a flexible optical fiber, which is then directed to a precise point on the target material. The high-energy laser beam melts, vaporizes, or removes the material, resulting in an accurate and refined cut. Advanced machines like ACCURL fiber laser cutters provide precise, efficient cutting, accommodating a range of materials with impressive speed and accuracy. Fiber laser systems are known for their compact design, minimal energy requirements, and high adaptability to various materials.

Key Stages in the Fiber Laser Cutting Process:

- Laser Generation: The fiber laser begins with generating light energy within the fiber, creating an intense beam.

- Beam Delivery System: The beam is directed toward the material through a system of mirrors or optical fibers, ensuring pinpoint accuracy.

- Material Interaction and Cutting: The laser beam interacts with the material, either melting or vaporizing it to achieve the desired cut shape.

- Cooling and Waste Management: Cooling systems manage the heat generated during the process, while waste management strategies handle material remnants, reducing environmental impact.

Why is Fiber Laser Cutting Considered Environmentally Friendly?

Fiber laser cutting stands out for its eco-friendly attributes, making it a preferred choice for companies committed to sustainability. Here are the primary reasons why fiber laser technology is considered environmentally beneficial:

Fiber laser cutting stands out for its eco-friendly attributes, making it a preferred choice for companies committed to sustainability. Here are the primary reasons why fiber laser technology is considered environmentally beneficial:

- Energy Efficiency: Fiber lasers use significantly less energy than traditional cutting methods, leading to lower electricity consumption and reduced greenhouse gas emissions.

- Waste Reduction: The precision of fiber laser cutting minimizes material waste, allowing businesses to make the most out of each piece of material.

- Low Emissions: Unlike other cutting processes that may produce toxic fumes, fiber laser cutting generates minimal emissions, making it a safer option for both workers and the environment.

- High Precision: Because fiber lasers achieve high accuracy, there is less need for rework or additional processing, conserving resources and materials.

Compared to traditional cutting technologies like CO₂ lasers and mechanical methods, fiber lasers achieve a cleaner, more resource-efficient cut, supporting a circular economy and sustainable manufacturing practices.

What Are the Key Advantages of Fiber Laser Cutting for Sustainable Practices?

Fiber laser cutting technology provides several advantages that directly support sustainable business practices:

- Reduced Energy Consumption: Lower power requirements help reduce energy costs and support a business’s green goals.

- Minimizing Material Waste: Precision cuts lead to fewer scrap materials, contributing to waste reduction.

- Non-Toxic Cutting Process: Unlike some cutting methods that involve chemicals, fiber laser cutting does not rely on hazardous substances, promoting a safer work environment.

- Enhances Material Recyclability: Fiber laser systems are compatible with recyclable materials, supporting closed-loop production systems and reducing environmental impact.

How Does Fiber Laser Cutting Contribute to Waste Reduction?

One of the most significant environmental benefits of fiber laser cutting is its contribution to waste reduction. By using focused laser beams, this technology ensures that cuts are accurate, minimizing the amount of excess material or “scrap” left behind. Compared to traditional cutting methods, which often result in irregular and wasteful cuts, fiber lasers make use of every part of the material with remarkable efficiency.

One of the most significant environmental benefits of fiber laser cutting is its contribution to waste reduction. By using focused laser beams, this technology ensures that cuts are accurate, minimizing the amount of excess material or “scrap” left behind. Compared to traditional cutting methods, which often result in irregular and wasteful cuts, fiber lasers make use of every part of the material with remarkable efficiency.

Through advanced software and precision control, fiber laser systems enable businesses to incorporate sustainable waste handling practices. Remnant materials from fiber laser cutting are often collected, recycled, or repurposed, thereby promoting a zero-waste manufacturing environment. These methods provide a practical pathway for businesses to embrace eco-friendly processes without sacrificing productivity or quality.

What Types of Materials Can Fiber Laser Cutting Process Sustainably?

Fiber laser cutting technology is highly versatile, capable of processing a wide variety of materials with minimal environmental impact. This adaptability not only broadens its application across industries but also contributes to sustainability by supporting efficient use of various materials. Here are some commonly used materials and their properties that make them suitable for fiber laser cutting.

- Stainless Steel: Known for its strength, corrosion resistance, and recyclability, stainless steel is ideal for fiber laser cutting. The precision of the laser allows intricate designs and complex shapes without sacrificing durability.

- Aluminum: This lightweight, recyclable metal is an excellent choice for fiber laser cutting. Its sustainable features, such as energy-saving benefits during production and ease of recycling, make it a top pick for green manufacturing.

- Copper: While copper has high thermal conductivity, which can complicate other cutting processes, fiber laser systems handle it effectively. The material’s conductivity makes it suitable for applications where heat management is critical.

- Titanium: Known for its durability and resistance to corrosion, titanium can be laser cut with high accuracy. Its recyclable nature and low environmental footprint in laser applications make it valuable for industries like aerospace and medical devices.

- Plastics (Environmentally Friendly, Recyclable Options): Fiber lasers can also process recyclable plastic materials, supporting eco-conscious manufacturing in electronics, packaging, and consumer goods.

Stainless Steel

Stainless steel’s durability and corrosion resistance make it a preferred material in industries that require long-lasting products. Fiber laser cutting allows stainless steel to be processed with minimal waste, making it a sustainable choice for applications in automotive, construction, and green building materials.

Aluminum

Aluminum’s lightweight properties contribute to energy savings, especially in industries like transportation, where reduced weight translates into fuel efficiency. The fiber laser cutting process minimizes waste while delivering precise results, aligning with sustainability goals.

Copper

Copper’s high thermal and electrical conductivity makes it essential in the electronics industry. Fiber lasers’ ability to handle this material efficiently means that copper can be processed with lower energy use compared to traditional cutting methods, reducing both waste and energy costs.

What Are the Environmental Impacts of Fiber Laser Cutting?

Fiber laser cutting has a smaller environmental footprint than many traditional cutting technologies. Its efficient energy use, minimal waste production, and low emissions make it an eco-friendly choice. When comparing fiber lasers with CO₂ lasers, the advantages become even more apparent. CO₂ lasers require more electricity and produce higher emissions, whereas fiber lasers operate at a fraction of the energy, resulting in lower overall costs and reduced carbon output.

Additionally, fiber laser cutting equipment has a longer operational life and requires less maintenance, further contributing to sustainability. Lifecycle analysis reveals that fiber laser technology’s efficiency and lower energy demands support long-term environmental goals. By implementing fiber laser systems, businesses can achieve significant reductions in greenhouse gas emissions and energy consumption, helping them align with sustainability initiatives and lower their carbon footprint.

How Does Fiber Laser Cutting Improve Energy Efficiency?

Fiber lasers are designed to optimize energy use, making them one of the most efficient cutting technologies available today. Here’s a breakdown of the energy-saving mechanisms that fiber lasers offer:

- Efficient Laser Beam Conversion: Fiber lasers convert electrical energy to laser light with a high degree of efficiency, minimizing energy loss and maximizing cutting power.

- Lower Power Requirements: Unlike traditional cutting systems, fiber lasers require less energy to operate, which translates to lower utility costs and reduced environmental impact.

- Minimal Thermal Impact: The precision and control of fiber lasers reduce excess heat generated during cutting, minimizing the need for extensive cooling systems.

Key Statistics on Energy Use Reduction:

- Fiber lasers can operate with up to 70% energy efficiency, making them substantially more economical than CO₂ lasers, which typically achieve around 20% efficiency.

- Businesses that switch to fiber lasers can reduce their energy consumption by as much as 50%, leading to long-term savings and a smaller environmental footprint.

What Makes Fiber Lasers More Sustainable Than Other Laser Types?

When comparing fiber lasers to other laser types, such as CO₂ and YAG lasers, the sustainability advantages of fiber lasers become clear. Here’s a quick overview of each type and its environmental impact:

- Fiber Lasers: High energy efficiency, minimal maintenance needs, and low waste make fiber lasers a top choice for sustainable practices.

- CO₂ Lasers: Although effective, CO₂ lasers consume more energy and produce more emissions, making them less eco-friendly.

- YAG Lasers: While YAG lasers are versatile, they lack the efficiency and durability of fiber lasers, often requiring more frequent replacements and higher energy input.

Pros and Cons of Laser Types (Focus on Sustainability Factors):

- Fiber Lasers: Pros include high efficiency, long operational life, and low emissions. Cons may include a higher initial investment.

- CO₂ Lasers: Pros include versatility for thicker materials, but cons involve higher energy consumption and maintenance.

- YAG Lasers: Pros include adaptability across applications, but cons are frequent maintenance and lower efficiency compared to fiber lasers.

In summary, fiber lasers offer the lowest environmental impact among laser types, making them the best option for companies committed to sustainable practices.

How Can Businesses Use Fiber Laser Cutting to Achieve Green Certifications?

Many businesses aim to achieve certifications that validate their commitment to sustainability, such as LEED and ISO 14001. Fiber laser cutting is well-suited for helping businesses align with these standards due to its low energy requirements, minimal waste, and resource efficiency.

Steps for Businesses to Achieve Green Certifications with Fiber Laser Cutting:

- Assess Energy Consumption: Calculate energy savings gained through fiber laser implementation.

- Minimize Waste: Track and document waste reduction achieved with fiber laser technology.

- Enhance Recyclability: Use recyclable materials and sustainable cutting methods.

- Document Sustainability Efforts: Maintain records of all eco-friendly practices for certification audits.

By following these steps, businesses can leverage fiber laser cutting to align with green standards, gaining recognition for their environmental efforts and appealing to eco-conscious customers.

Which Industries Benefit Most from Sustainable Fiber Laser Cutting?

Fiber laser cutting has applications across multiple industries, each of which benefits uniquely from the sustainability aspects of this technology:

Fiber laser cutting has applications across multiple industries, each of which benefits uniquely from the sustainability aspects of this technology:

- Automotive: Reduces material waste in car part production, leading to lighter and more fuel-efficient vehicles.

- Electronics: Enables precise cuts for small components, essential in minimizing waste in electronics manufacturing.

- Aerospace: Ideal for processing strong, lightweight materials that enhance fuel efficiency.

- Medical Devices: Offers precise, contamination-free cuts, crucial for creating sterile medical tools and devices.

- Green Construction Materials: Supports the production of recyclable metal components, contributing to sustainable building practices.

What Are the Cost Implications of Implementing Fiber Laser Cutting?

While the initial investment in fiber laser cutting machines may be significant, the long-term savings make it a financially sound decision for businesses prioritizing sustainability. Here’s a breakdown of the cost factors involved:

- Machine Costs: Depending on the model and features, fiber laser machines can vary in price, with higher efficiency models generally commanding a premium.

- Maintenance Savings: Fiber lasers have lower maintenance needs compared to other cutting technologies, reducing downtime and maintenance costs.

- Operational Savings: Energy efficiency leads to lower electricity bills, while reduced waste contributes to savings on materials and disposal fees.

How Much Does a Fiber Laser Cutting Machine Cost?

Fiber laser machines typically range from $30,000 to over $200,000, depending on power, features, and brand. Although the initial cost is higher, fiber lasers often have a long operational life and a high return on investment (ROI), thanks to their energy efficiency and minimal maintenance needs.

What Are Key Maintenance Considerations for Sustainable Fiber Laser Operations?

To ensure ongoing efficiency and sustainability, fiber laser cutting systems require regular maintenance. Here are some best practices for sustainable maintenance:

- Regular Inspection for Energy Efficiency: Routine inspections help identify areas where energy efficiency can be improved.

- Waste Management and Recycling Practices: Establish processes for recycling scrap materials, contributing to a circular economy.

- Cooling Systems that Reduce Water Waste: Efficient cooling systems prevent excessive water use, helping businesses conserve this vital resource.

Are There Alternative Sustainable Cutting Technologies?

While fiber laser cutting offers numerous sustainability benefits, other cutting technologies also present eco-friendly options for specific applications. Here’s how some of the alternative methods compare in terms of sustainability:

- Waterjet Cutting: This method uses a high-pressure stream of water, sometimes combined with abrasives, to cut through materials. It produces minimal heat, reducing thermal stress on materials and resulting in precise cuts. However, waterjet cutting requires significant water usage, which could be a drawback for some sustainability-focused businesses.

- Plasma Cutting: Plasma cutting employs electrically conductive gas to melt and cut materials. Though it’s efficient and effective for thicker metals, plasma cutting has higher energy consumption and may produce emissions that require proper ventilation.

- Mechanical Cutting Methods: Traditional methods such as sawing and milling use physical force to remove material. While these methods can be eco-friendly when optimized for efficiency, they lack the precision and minimal waste features of fiber lasers.

Comparison of Alternative Cutting Methods:

- Waterjet Cutting: Pros include low thermal impact and high precision, but cons involve water consumption and potential waste management issues.

- Plasma Cutting: Pros include affordability and the ability to cut thick materials; cons are higher energy use and emissions.

- Mechanical Cutting: Pros include simplicity and low environmental impact if optimized, while cons are limited precision and higher material waste compared to lasers.

Fiber laser cutting remains a top choice for sustainability due to its lower energy demands, waste reduction, and broad material compatibility, making it ideal for industries committed to greener operations.

How to Optimize Fiber Laser Cutting for Maximum Sustainability

For businesses looking to maximize the sustainability of their fiber laser cutting operations, certain practical adjustments can make a significant difference. Here are some tips to enhance eco-friendliness:

For businesses looking to maximize the sustainability of their fiber laser cutting operations, certain practical adjustments can make a significant difference. Here are some tips to enhance eco-friendliness:

- Choose the Right Material Thickness: Selecting the appropriate thickness for each material reduces unnecessary energy use and waste.

- Minimize Power Settings for Energy Conservation: Adjusting the laser power settings based on material requirements helps save energy.

- Use Nesting Software to Reduce Waste: Nesting software arranges parts to maximize material usage, lowering scrap production and increasing efficiency.

Safety Tips for Sustainable Fiber Laser Cutting

Maintaining a safe and eco-friendly workspace is essential when implementing sustainable practices in laser cutting. Here are some safety tips that also support sustainability:

- Air Quality Management in the Workspace: Use proper ventilation systems to minimize airborne particles, maintaining a clean and safe environment.

- Safe Handling and Disposal of Cutting By-products: Ensure that any waste materials, especially hazardous ones, are disposed of responsibly to prevent environmental harm.

- Training Staff on Sustainable Operation: Educate staff on best practices for sustainable laser cutting to ensure consistent, eco-conscious operations.

What Are Common Mistakes to Avoid in Fiber Laser Cutting for Sustainability?

Avoiding common pitfalls in fiber laser cutting can enhance both the efficiency and sustainability of operations. Here are some mistakes to watch for:

- Using Unnecessary Power Levels: Running the laser at higher power than needed increases energy consumption and wears out equipment faster.

- Ignoring Waste Recycling Processes: Failing to recycle scrap materials results in unnecessary waste and missed opportunities for sustainable practices.

- Failing to Maintain Equipment for Energy Efficiency: Regular maintenance is crucial for keeping fiber laser equipment in optimal condition, preventing energy loss and minimizing emissions.

How Do Sustainable Practices in Fiber Laser Cutting Impact Brand Reputation?

Implementing sustainable practices in fiber laser cutting can significantly enhance a brand’s reputation. Customers increasingly favor companies that prioritize environmental responsibility, and incorporating eco-friendly cutting methods can set businesses apart in competitive markets. By actively promoting their sustainable practices, businesses can build trust with eco-conscious customers, drive customer loyalty, and attract new clients who value corporate responsibility.

Brands that lead with sustainable innovations often find that their efforts pay off in positive customer perceptions and increased market share. For instance, companies in the automotive or aerospace sectors may highlight their waste reduction and energy-saving practices in fiber laser cutting as proof of their commitment to sustainability, enhancing their appeal to both consumers and corporate partners.

Conclusion

Fiber laser cutting plays a pivotal role in advancing sustainable manufacturing practices. Its energy efficiency, precision, and waste-reducing capabilities make it an ideal choice for businesses looking to minimize their environmental footprint while maintaining high production standards. As companies across industries—from automotive to electronics—continue to prioritize sustainability, fiber laser cutting provides an effective solution that aligns with green goals and supports eco-friendly manufacturing processes.

The future of sustainable manufacturing will undoubtedly see fiber laser cutting as a fundamental technology, enabling businesses to reduce emissions, conserve resources, and achieve sustainability certifications. By integrating fiber laser cutting into their production practices, American businesses can lead the way toward a greener, more responsible manufacturing landscape.

681 Views