Technology developments are now the primary factor in corporate growth and success in the ever-changing world of contemporary manufacturing. You can use CNC (computer numerical control) machines to stand out as a game-changer among the cutting-edge inventions that have transformed the industry. With its unparalleled precision, efficiency, and adaptability, this advanced computer-controlled equipment have completely changed how industrial operations are carried out.

With a predicted demand for over 2800 CNC machines by 2030, it’s evident that this technology is set to play a pivotal role in shaping the future of businesses worldwide. In this blog post, we’ll explore the transformative power of CNC machines. delve into their benefits and how they can empower your business to thrive and conquer new heights of success.

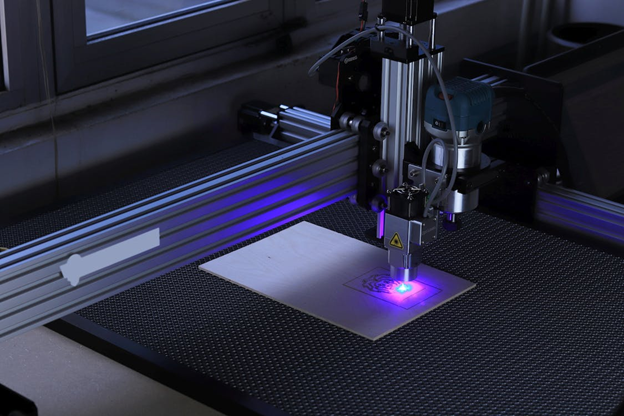

Understanding CNC Machines

CNC machines are a product of advanced automation and computer-controlled technology, revolutionizing modern manufacturing processes. These advanced robots execute operations with unparalleled precision and accuracy thanks to pre-programmed instructions. However, the knowledge of a reliable CNC machining company becomes essential to completely realize their potential and maximize their capabilities.

CNC machines are a product of advanced automation and computer-controlled technology, revolutionizing modern manufacturing processes. These advanced robots execute operations with unparalleled precision and accuracy thanks to pre-programmed instructions. However, the knowledge of a reliable CNC machining company becomes essential to completely realize their potential and maximize their capabilities.

A CNC machining business is essential to the industrial sector because it provides a variety of specialized services that make the best use of CNC machines. Professionals with extensive understanding of CNC programming, machine operation, and material handling work for these businesses. They can convert design criteria into exact instructions that CNC machines can perfectly follow thanks to their experience.

Additionally, CNC machining businesses frequently keep a variety of materials in stock, from metals to plastics, allowing them to adapt to the demands of different projects.

They collaborate closely with clients, understanding their requirements and offering valuable insights to optimize designs for efficient manufacturing. This collaboration ensures that the final product meets both the client’s expectations and the CNC machines’ capabilities.

Precision and Accuracy

CNC machines are renowned for their ability to eliminate human errors during the production process. In stark contrast to manual machining, which often leads to slight discrepancies, CNC machines consistently deliver flawless and precise results. This exceptional level of precision ensures a consistent standard of product quality, allowing businesses to establish a reputation for excellence and reliability within the market. Customers can trust that each item produced by the CNC machines will meet the highest standards, fostering confidence and loyalty in the brand.

Increased Productivity and Efficiency

In the frenetic world of business that we have today, time is of the utmost importance. CNC machines excel in boosting productivity by operating at high speeds, significantly reducing production times. This leads to increased output and faster turnaround times, enabling businesses to meet tight deadlines and fulfill customer orders promptly. Moreover, CNC machines minimize setup times, seamlessly transitioning between different tasks with ease. This optimization of operational efficiency allows businesses to maximize their productivity levels and maintain a competitive edge in the market.

Cost Savings

Despite the initial investment required, CNC machines offer substantial long-term cost savings for businesses. By optimizing material utilization, these machines minimize wastage, reducing material expenses and ultimately cutting down on production costs. Additionally, the decreased reliance on physical work results in longer-term labor costs that are cheaper. Businesses may then increase their profitability and put their savings back into expanding and developing their companies.

Diversification of Products

CNC machines’ adaptability is a game-changer for companies looking to expand their product lines. Infinite options for developing new product lines are made possible by CNC machines’ capacity to deal with a variety of materials, including metals and polymers.

Businesses can explore innovative designs and execute complex projects that were once considered unfeasible with conventional methods. This adaptability empowers companies to cater to a broader customer base, tapping into different markets and staying relevant in a rapidly changing industry.

Innovation and Customization

In today’s dynamic business landscape, innovation and customization are key drivers of success. CNC machines play a pivotal role in fostering innovation by facilitating rapid prototyping and iterative design processes. Businesses can quickly develop and refine new products, reducing time-to-market and staying ahead of their competitors. Additionally, CNC machines enable businesses to offer customized products tailored to meet individual customer preferences. This personalization enhances customer satisfaction, fosters brand loyalty, and builds long-lasting customer relationships.

Conclusion

CNC machines have become indispensable tools for businesses aiming to achieve growth and success in a competitive market. Their precision, efficiency, cost-effectiveness, and customization capabilities provide numerous advantages that drive business expansion. By embracing CNC technology and leveraging its transformative power, businesses can enhance productivity, boost product quality, and unlock new opportunities for innovation, ultimately leading to sustainable growth and success.

1425 Views